If you’re an employer or mobile crane operator, it’s your responsibility to ensure that everyone on the job site is aware of the hazards of using this equipment. By routinely inspecting your cranes and following safe work practices, you can help keep your team injury-free and avoid costly citations and unnecessary accidents.

Our downloadable mobile crane inspection checklists are intended as a starting point for you to customize, based on your operations. These meet all of OSHA’s federal safety regulations. However, your state-specific standards may not be identical, and additional rules may apply based on your industry.

We are committed to safety and provide comprehensive mobile crane safety training programs. NCT’s mobile crane operator school courses are designed to meet or exceed the requirements of OSHA 1926.1412 and cover the safe operation of all types of mobile cranes. We’ve helped thousands of operators acquire CCO certification.

OSHA standard 1926.1412 says a qualified and competent person needs to inspect the crane. According to the regulation, “At least every 12 months the equipment must be inspected by a qualified person in accordance with paragraph (d) of this section (each shift)…”

“Qualified” means one who, “by possession of a recognized degree, certificate, or professional standing, or who by extensive knowledge, training, and experience, has successfully demonstrated his ability to solve or resolve problems relating to the subject matter, the work, or the project.”

OSHA defines a competent person as “one who is capable of identifying existing and predictable hazards in the surroundings or working conditions which are unsanitary, hazardous, or dangerous to employees, and who has the authorization to take prompt corrective measures to eliminate them.”

Inspections are required under the following conditions:

Common Safety Hazards

Unlevel cranes are a common cause of accidents. If the crane is not level, it can fall over while lifting heavy loads or even just running the boom out. Additionally, if a crane is not inspected before use, there could be structural damage to the boom or mast, which can cause it to buckle. Equipment that has become somehow damaged can be a major hazard for those on the job site.

Another common potential hazard on construction sites running mobile cranes is unstable ground conditions, especially in poor weather. If the crane drives off the excavation edge or tips in sideways, not only will repairs be necessary, there could also be extensive damage done to the site.

When it comes to mobile cranes, a number of accidents can occur if mobile cranes are not inspected before operation. To reduce the risk of accidents, crane operators need to be aware of the potential dangers.

If a crane’s boom or load line comes into contact with a power line, it can become electrically charged, even if the power line itself isn’t live—very dangerous for workers nearby.

When a crane’s rigging fails to hold its load, it can cause the load to fall or swing dangerously. This could lead to injury or death to those around the crane if they are hit by falling debris or other objects toppled in the load’s path.

If the crane’s load is too heavy for the structure it is mounted on, this could cause it to collapse. This can injure or kill people working nearby on in the surrounding area.

Cranes tip over when the crane’s center of gravity gets shifted and the weight at the top causes the whole thing to keel over. This can crush or kill nearby people and those working on the ground.

Swing-radius accidents occur when a crane is not operated correctly or safely, causing its load to swing erratically or dangerously. This could cause injury or death to those near the crane if it’s hanging over them.

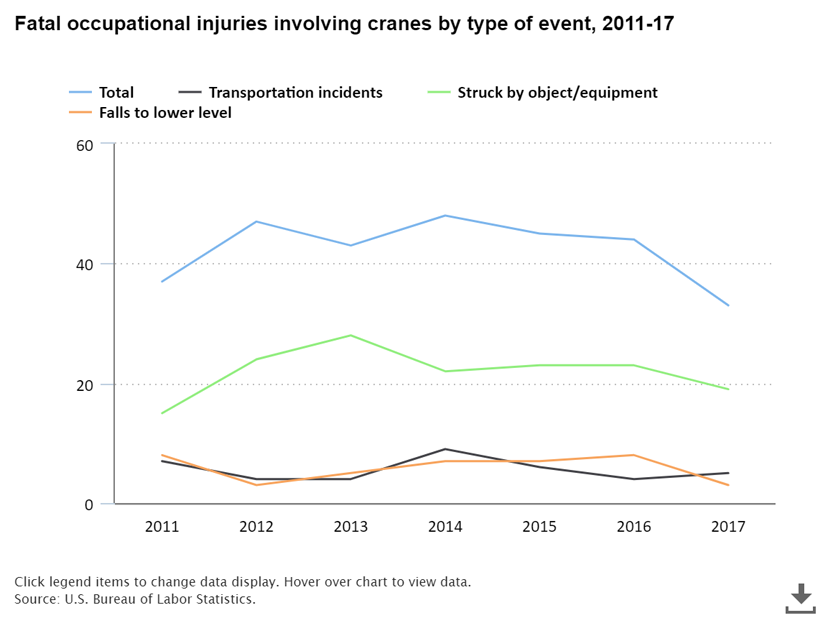

In 2017, Dr. David Michaels, OSHA’s assistant secretary of labor, said: “Before OSHA was created 43 years ago, an estimated 14,000 workers were killed on the job every year. It means 38 fatalities and injuries a day.”

The best way for operators and employers to avoid crane accidents is to have a comprehensive safety plan, including regular inspections of equipment, safe work practices, and proper training for all those working with the crane. A daily mobile crane inspection checklist can help with this.

Although documentation of a daily checklist is not required, an inspection every shift is. The downloadable mobile crane inspection checklists here are intended as a starting point for you to customize, based on your operations. These meet all of OSHA’s federal safety regulations. However, your state-specific standards may not be identical, and additional rules may apply based on your industry.

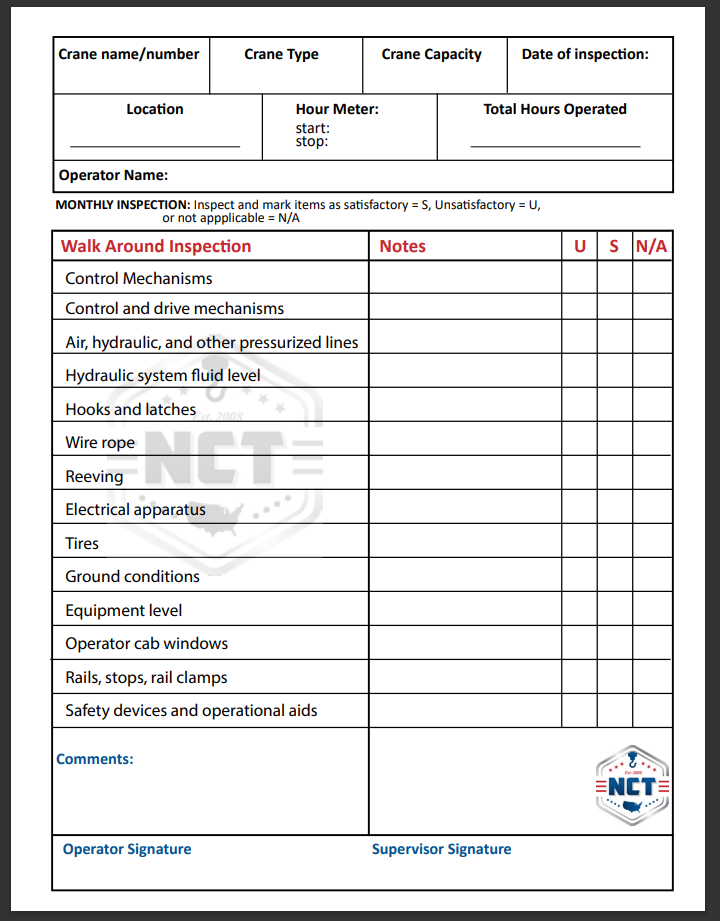

If you run a mobile crane, you must provide regular monthly inspection documentation. This monthly mobile crane inspection checklist meets all the federal regulations. As mentioned, make sure it matches your state-specific requirements and customize it for your specific use.

NCT is the preferred heavy equipment operator training school for crane operators who work in public and private utilities, road and bridge construction, mining operations, oil and gas, forestry and public land management, and more. We are headquartered in Washoe Valley, Nevada, with training centers across the U.S. and customized on-site training and in-person classes. Our NCCCO certified heavy equipment instructors and trainers include military veterans, experienced riggers, signal persons, and crane inspectors. Find out which crane training classes are best for you or your company.

https://www.nationwidecranetraining.com/wp-content/uploads/2021/06/Nationwide_Crane_Training_NCT_logo.png 0 0 resultsAdmin https://www.nationwidecranetraining.com/wp-content/uploads/2021/06/Nationwide_Crane_Training_NCT_logo.png resultsAdmin 2022-03-22 18:39:00 2024-06-17 08:52:54 FREE Daily and Monthly Mobile Crane Inspection Checklists